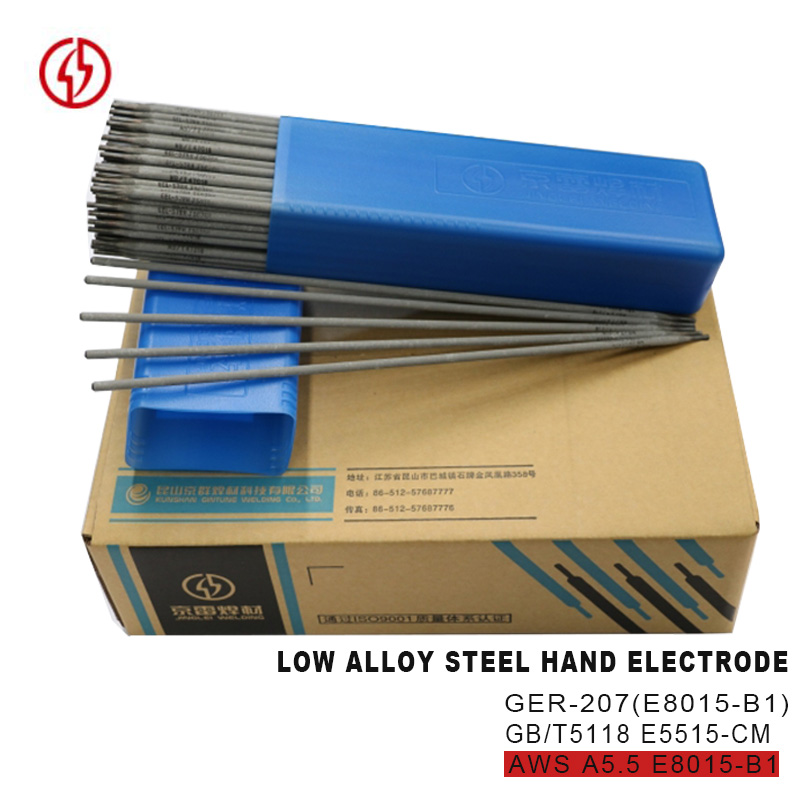

AWS E8015-B1 Low-alloy steels Manual lantarki waldi kayan

Aikace-aikace & Standard&Lura:

GER-207 zafi resistant karfe hannun walda sanda (R207) 0.5% Cr-0.5% Mo karfe waldi sanda ya dace da walda CrMo pearlite zafi resistant karfe da kuma high zafin jiki, high matsa lamba bututu, sinadaran kwantena da sauran m karfe, kamar 12CrMo tube farantin, A335-P2 tube, A387Gr.2 farantin. Yanayin walda: preheating da tashar (Layer) zafin jiki: 160 ~ 190 ℃; 3. Heat magani: 690 ± 15 ℃x1h zafi magani ne da za'ayi bisa ga misali bukatun na waldi kayan.

AWS E8015-B1 nau'in lantarki na hannu don karfe mai jure zafi ya dace da waldawa CrMo pearlite zafi mai jurewa karfe (kamar 12CrMo, da dai sauransu) da zafin jiki, babban bututun matsin lamba, kwandon sinadarai da sauran karfe mai dacewa. Kafin walda, dole ne a toya wutar lantarki a kusan 350 ℃ na 1h, sannan a yi amfani da shi tare da yin burodi. Kafin walda, dole ne a tsabtace walda daga tsatsa, mai, ruwa da sauran ƙazanta.

Siffofin

AWS E8015-B1 (R207) nau'in na'urar waldawa ta hannu don ƙarfe mai jure zafi shine ƙarancin sodium hydrogen nau'in walƙiya na hannu, barga arc, ƙarancin fantsama, ƙira mai kyau, sauƙi desagging, aikin X-Ray yana da kyau. Ana amfani da na'urar walda ta hannu sosai a cikin wutar lantarki, injiniyan wutar lantarki, petrochemical da sauran masana'antu, nau'in Cr-Moh da Mn-Mo da aka fi amfani da shi da ƙarfe mai jure zafi da Cr-Mo tushe Multi-element alloy heat resistant karfe. Har ila yau wajibi ne a yi amfani da hanyar preheating kafin sanya waldi da waldi na yau da kullun don walƙiya mai jure zafi. Idan weldment yana da ƙarfi, ya kamata a preheated gaba ɗaya. Bayan walda, ya kamata a kiyaye walda a sama da zafin jiki na preheating na sa'o'i da yawa, sannan a sanyaya a hankali.

Kamfanin & Factory

Gabatarwar abun da ke ciki da kayan aikin injiniya

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T dokokin | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| Dokokin AWS | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| MISALI DARAJAR | 0.078 | 0.72 | 0.35 | 0.56 | 0.53 | 0.016 | 0.01 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||||||

| GB/T dokokin | 460 | 550 | 690*1 | - | 17 | |||||||||

| Dokokin AWS | 460 | 550 | 690*1 | - | 19 | |||||||||

| MISALI DARAJAR | 490 | 590 | 690*1 | 90/Yawan zafin jiki | 23 | |||||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

BAYANIN CIKI:

| SANARWA | TSORO | PCS/1KG | NUNA/1KG | |||

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | mm 350 | 27 PCS | 5KG | |||

| 4.0mm | mm 350 | 16 PCS | 5KG | |||

| 5.0mm ku | mm 350 | 12 PCS | 5KG | |||

Al'amuran Al'ada

Takaddun shaida

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T dokokin | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| Dokokin AWS | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| MISALI DARAJAR | 0.078 | 0.72 | 0.35 | 0.56 | 0.53 | 0.016 | 0.01 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||||||

| GB/T dokokin | 460 | 550 | 690*1 | - | 17 | |||||||||

| Dokokin AWS | 460 | 550 | 690*1 | - | 19 | |||||||||

| MISALI DARAJAR | 490 | 590 | 690*1 | 90/Yawan zafin jiki | 23 | |||||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

BAYANIN CIKI:

| SANARWA | TSORO | PCS/1KG | NUNA/1KG | |||

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | mm 350 | 27 PCS | 5KG | |||

| 4.0mm | mm 350 | 16 PCS | 5KG | |||

| 5.0mm ku | mm 350 | 12 PCS | 5KG | |||