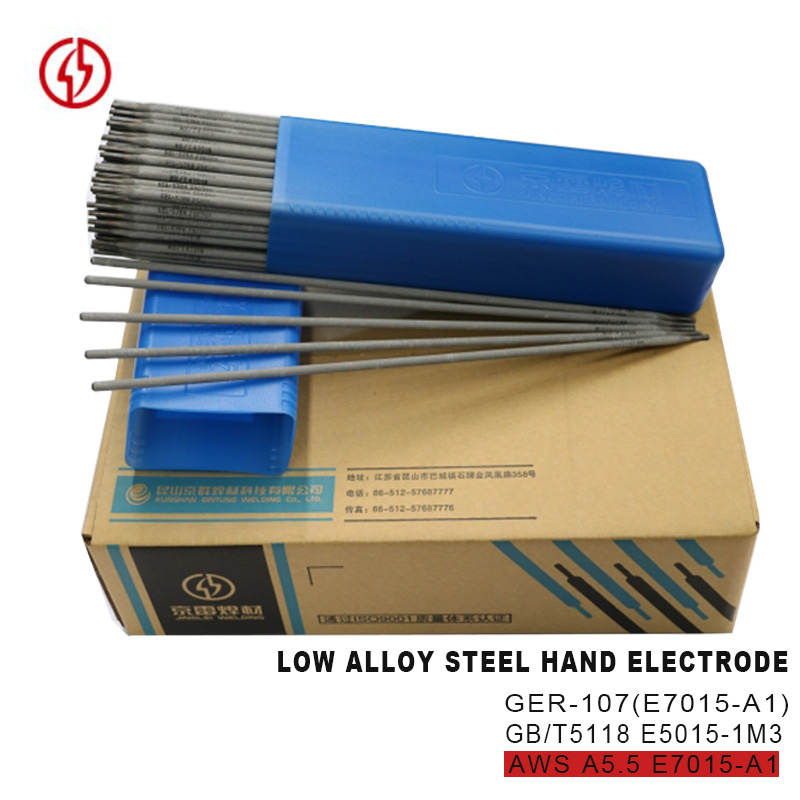

AWS E7015-A1 Low-alloy steels Manual lantarki walda kayan haɗi

Aikace-aikace & Standard&Lura:

E7015 irin low gami karfe hannun lantarki dace waldi aiki zafin jiki a kasa 510 ℃ tukunyar jirgi bututu, zafi Exchanger da sauran lokatai, kamar ASTM A204 da A335-P1 bututu;

Dole ne a bushe wutar lantarki kafin amfani, kiyaye ɗan gajeren baka, yin amfani da hanyar waldawa ta baya, kauce wa faruwar porosity a baka; Ya kamata a kiyaye ƙarancin hydrogen a duk lokacin aikin walda. Low gami karfe electrode selection, yawanci bisa ga sinadaran abun da ke ciki na karfe, inji Properties, crack juriya da sauran bukatun, amma kuma daga waldi tsarin siffar, aiki yanayi, danniya da waldi kayan aiki da sauran al'amurran da m la'akari. Idan ya cancanta, za a gudanar da gwaje-gwajen aikin walda don tantance wutar lantarki kuma za a ɗauki matakan da suka dace.

Siffofin

1. Low sodium hydrogen electrode, ƙara 0.5% Mo don inganta ƙarfin weld da juriya na lalata;

2. Stable arc, ƙarancin fantsama, ƙira mai kyau, mai sauƙin cirewa, aikin X-Ray yana da kyau.

Kullum zabi m electrode bisa ga ƙarfin karfe sa, a lokaci guda kuma bukatar karfe weldability, miƙa mulki na iyaye karfe aka gyara, kuskura ya amsa da tsarin size, siffar, tsagi da danniya taro dalilai, kamar m. la'akari, da sanyaya gudun waldi ne ma girma, shi ne mafi girma ƙarfi, weld titi kayayyakin sauƙi crack da m yanayi, sau da yawa za a iya zabar wasu kasa da ƙarfin iyaye karfe lantarki.

Kamfanin & Factory

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T dokokin | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| Dokokin AWS | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| MISALI DARAJAR | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||||||

| GB/T dokokin | 390 | 490 | 620*1 | - | 22 | |||||||||

| Dokokin AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| MISALI DARAJAR | 477 | 570 | 620*1 | 150/Yawan zafin jiki | 28 | |||||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

BAYANIN CIKI:

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | mm 350 | 27 PCS | 5KG | |||

| 4.0mm | mm 350 | 16 PCS | 5KG | |||

| 5.0mm ku | mm 350 | 12 PCS | 5KG | |||

Al'amuran Al'ada

Takaddun shaida

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T dokokin | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| Dokokin AWS | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| MISALI DARAJAR | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||||||

| GB/T dokokin | 390 | 490 | 620*1 | - | 22 | |||||||||

| Dokokin AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| MISALI DARAJAR | 477 | 570 | 620*1 | 150/Yawan zafin jiki | 28 | |||||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

BAYANIN CIKI:

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | mm 350 | 27 PCS | 5KG | |||

| 4.0mm | mm 350 | 16 PCS | 5KG | |||

| 5.0mm ku | mm 350 | 12 PCS | 5KG | |||