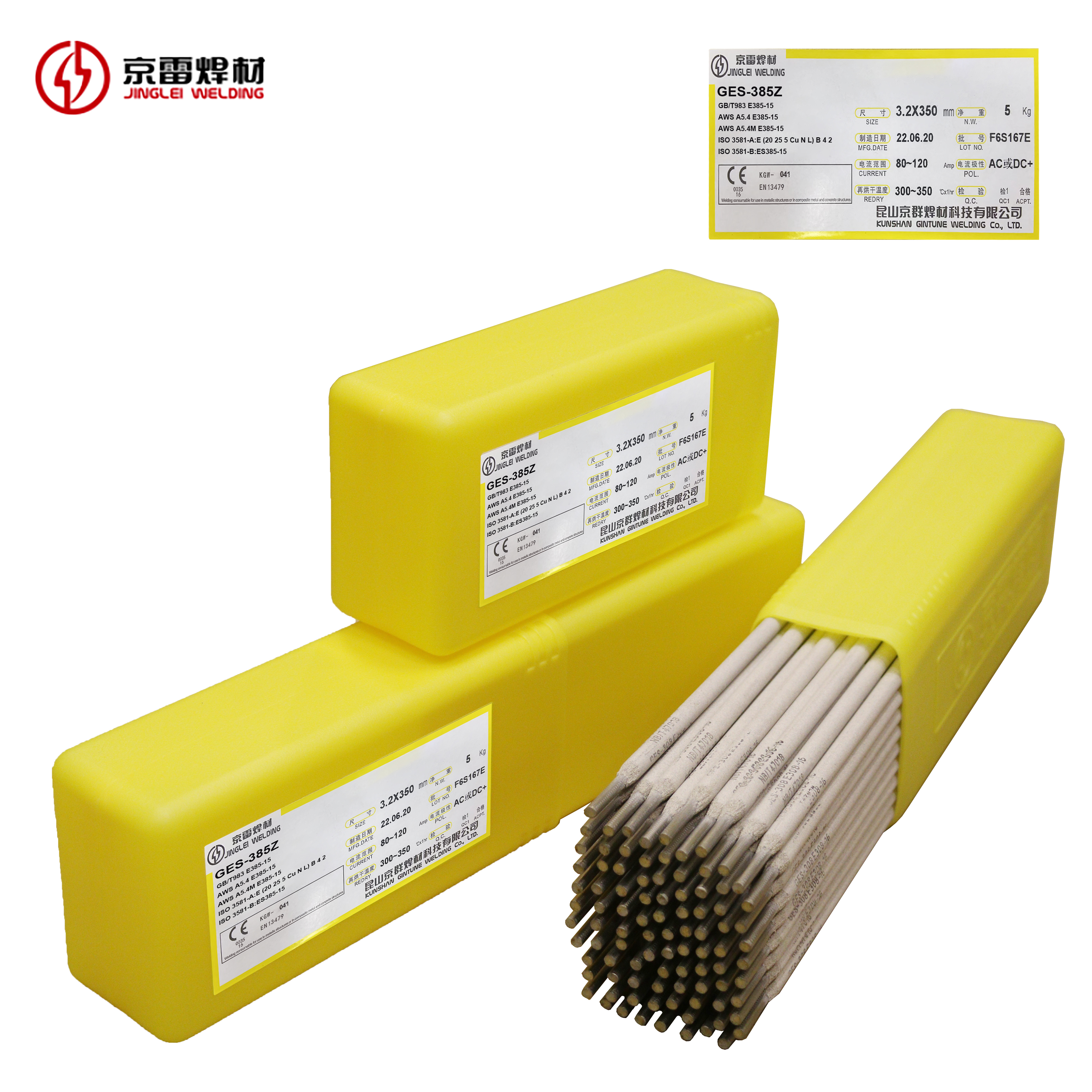

Bakin Karfe Manual Electrode E385-15 Cryogenic ajiya kayan walda

FASSARAR welding

Kar a bar tambayoyin

Ci gaba da ratsa ku

Rashin kwanciyar hankali

Gyaran mara kyau

Wuce kitse

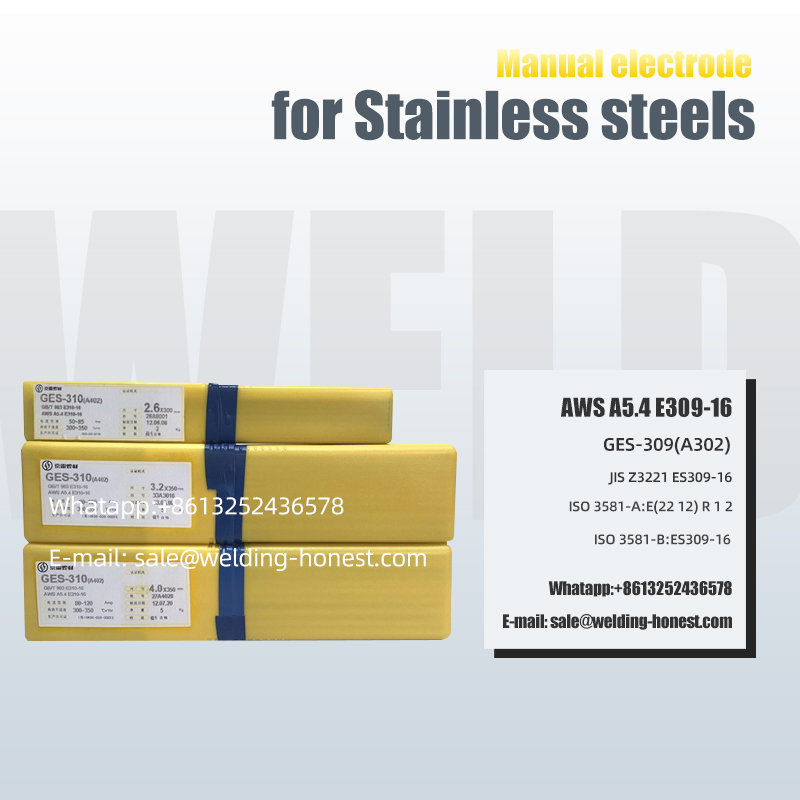

Yawancin lokaci ana amfani da su a cikin hasumiya mai ƙarfi na acid iri-iri, tanki, bututun bututu da kwandon ajiya, kamar walda 904L.

Low hydrogen tsarki austenitic bakin karfe hannu electrode, babban abun da ke ciki ne low C-20% Cr-25% Ni-5% Mo-2% Cu.

Ripple lafiya

Kyakkyawan juriya na lalata, na iya tsayayya da sulfuric acid,

Phosphoric acid uniform lalata, ƙarƙashin yanayin juriya ga kowane zafin jiki

maida hankali acetic acid lalata, iya yadda ya kamata warware halide pitting lalata, Ramin lalata,

damuwa da lalata da sauran matsalolin;Kyakkyawan aikin walda, kyakkyawan juriya na wuta,

mai kyau porosity juriya, barga inji Properties na narkakkar karfe.

Sauƙi slagging

Sigar Samfura

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Sauran |

| GB/T dokokin | 0.031 | 2.27 | 0.66 | 0.019 | 0.003 | 25.5 | 21.1 | 5.15 | 1.68 | - |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | IMAPACT DARAJAR J/℃ | Maganin zafi °C*h | ||||

| GB/T dokokin | 615 | 38 | - | - | ||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| WUTAR LANTARKI (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Tallafin masana'anta

Samfurin ya dace da a

fadi da kewayon aikace-aikace

FASSARAR welding

-

Kayan walda don masu shiru

-

Sanmen Makaman Nukiliya

-

180,000 tons Capesize babban jigilar kaya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Sauran |

| GB/T dokokin | 0.031 | 2.27 | 0.66 | 0.019 | 0.003 | 25.5 | 21.1 | 5.15 | 1.68 | - |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | IMAPACT DARAJAR J/℃ | Maganin zafi °C*h | ||||

| GB/T dokokin | 615 | 38 | - | - | ||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| WUTAR LANTARKI (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||