Whatsapp:+8613252436578 E-mail:sale@welding-honest.com

1. rarrabawa

Dangane da adadin abun ciki na carbon, ana iya raba karfen carbon zuwa kashi uku masu zuwa:

1) Low carbon karfe C% ≤ 0.25

2) Matsakaicin carbon karfe 0.25

3) Babban carbon karfe C%> 0.6

Karamin kartani

Tsakiyar Carbon

High-Carbon

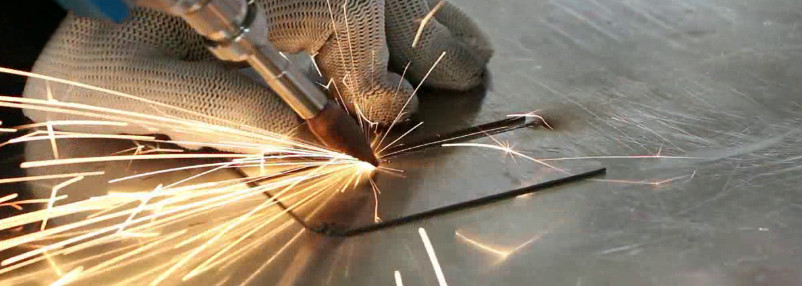

2. weldability analysis

Adadin abun ciki na carbon shine mahimman tunani don haɓaka hanyoyin walda. Yayin da abun ciki na carbon ya karu, ƙarfi da taurin suna karuwa, yayin da filastik da taurin suna raguwa, yayin da damuwa ya karu. Idan aka kwatanta, ƙananan abubuwan da ke cikin carbon, mafi kyawun walƙiya, sabili da haka, abubuwan da ke cikin carbon shine ma'auni don yin hukunci game da wahalar carbon karfe waldi, kuma ya kamata a ɗauki matakai daban-daban na walda don abun ciki na carbon daban-daban.

3. Tsarin walda

Zaɓin kayan walda na ƙarfe na carbon ya bi ka'idar "ƙarfi daidai"

1. Low carbon karfe (wanda aka fi sani da m karfe)

Makin ƙarfe na yau da kullun kamar Q235 (wanda aka fi sani da A3 karfe), Q255, da sauransu, gabaɗaya baya ɗaukar matakan musamman lokacin walda, ba preheating ko postheating.

2. Matsakaicin carbon karfe

Karfe da aka fi amfani da su kamar 30 #, 45 #, da dai sauransu, 45 # shine kayan aikin masana'antar gani da fayiloli, yana da kyau a yi amfani da kayan walda mara ƙarancin hydrogen tare da juriya mai kyau, preheating 100-200 °C; Idan bai dace da preheat ba, Cr-Ni austenitic bakin karfe walda kayan za a iya zaba.

3. High carbon karfe

Makin karfe da aka fi amfani da su kamar 60Si2Mn, T8, T10 da sauransu. 60Si2Mn wani ƙarfe ne na bazara na yau da kullun, galibi ba sa aiwatar da maganin walda, galibi ana amfani da shi azaman sake waldawa, yakamata ya zama 250-350 ° C preheating, walƙiya dole ne a buge shi don kawar da damuwa, kuma 650 ° C bayan zafin jiki, na iya kuma zabi Cr-Ni austenitic bakin karfe walda kayan

Na hudu, m karfe hannu electrode janar waldi muhimmanci:

Electrode bushewa zafin jiki

| Abu | Nau'in fata | Samfura | Zazzabi | Lokaci |

| Low carbon karfe da high ƙarfi karfe | Low nau'in hydrogen | E7016, E7048, E7015, E7015-G | 300-350 ℃ | 60 min |

| E7015, E8015-G, E9016-G, E9015-D1, E10015-D2, E12015-G | 330-380 ℃ | |||

| Babban tauri da ƙarancin nau'in hydrogen | E7016-G, E7015-G, E8015-G, E9015-G, E10015-G | 350-380 ℃ | 60 min | |

| Iron foda low hydrogen irin | E7018, E7018-1 | 300-350 ℃ | 60 min | |

| E8018-G, E918-G, E9018-M, E10018-D2, E10018M, E11018-G, E11018M, E12018-G | 350-380 ℃ | 60 min |

2. Ya kamata a cire danshi, mai, tsatsa, da dai sauransu a saman kayan tushe

3. Yi amfani da hanyar gaba don walda don guje wa stomata a wurin farawa

Ya kamata a yi amfani da gajeriyar walda ta baka, irin su igiyoyin motsi, kuma girman oscillation bai kamata ya wuce diamita na waya sau uku ba.

Lokacin aikawa: Oktoba-13-2022