A yayin aiwatar da aiki mai wahala, fasa yakan haifar da matsaloli kamar sake aiki da dawowar abokin ciniki. Hardfacing surfacing ne daban-daban daga general tsarin waldi, da kuma hukunci da hankali shugabanci na fasa su ma sun bambanta. Wannan labarin yayi nazari kuma yayi magana akan bayyanar faɗuwa gama gari a cikin aiwatar da tauri mai jure lalacewa.

1. Ƙaddamar da fasa

A halin yanzu, a cikin gida da ma na duniya, babu wani ma'auni na gabaɗaya don tsagewar lalacewa ta hanyar lalacewa mai wuya. Babban dalili shi ne cewa akwai nau'ikan yanayin aiki da yawa don samfuran lalacewa mai wuyar gaske, kuma yana da wahala a ayyana ma'auni daban-daban masu amfani da fashe a ƙarƙashin sharuɗɗan. Koyaya, bisa ga gwaninta a cikin aikace-aikacen kayan walda masu juriya masu wahala a fagage daban-daban, ana iya daidaita digiri da yawa da yawa, da kuma ka'idodin yarda a masana'antu daban-daban:

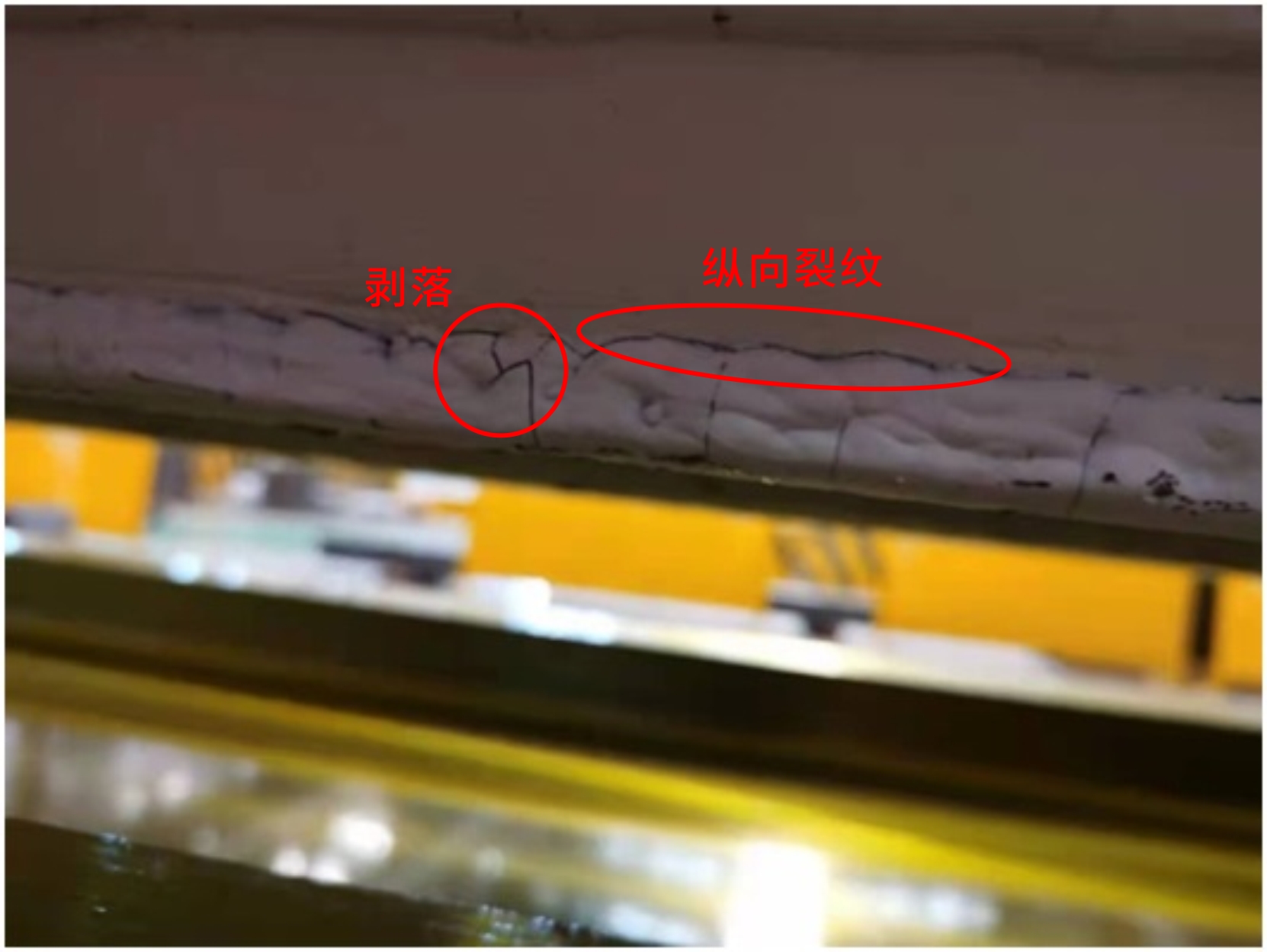

1. Jagorancin fashe yana layi ɗaya da ƙwanƙwasa walda (ƙwanƙwasa mai tsayi), ci gaba da fashewa mai jujjuyawa, fashewar kara zuwa tushe karfe, spalling.

Muddin ɗaya daga cikin matakan tsaga da aka ambata a sama ya cika, akwai haɗarin cewa gabaɗayan saman da ke sama zai faɗi. Ainihin, komai mene ne aikace-aikacen samfurin, ba za a yarda da shi ba kuma ana iya sake yin aiki da sake siyarwa.

2. Akwai tsage-tsafe da katsewa kawai

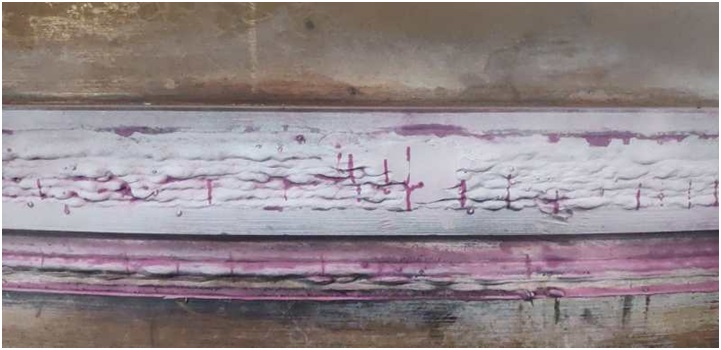

Domin workpieces da suke cikin lamba tare da m kayan kamar tama, sandstone, da kwal ma'adinai, da taurin da ake bukata ya zama high (HRC 60 ko fiye), da high-chromium waldi kayan da ake amfani da gabaɗaya don surfacing waldi. Za a samar da lu'ulu'u na carbide na chromium da aka kafa a cikin walda saboda sakin damuwa. Ana karɓuwa da faɗuwa matuƙar cewa jagorar tsaga ta kasance daidai gwargwado ga ƙullin walda (mai juyawa) kuma ya daina. Duk da haka, har yanzu za a yi amfani da adadin tsaga don kwatanta fa'idodi da rashin amfani da abubuwan amfani da walda ko hanyoyin hawan igiyar ruwa.

3. Babu tsatsa waldi

Don kayan aiki irin su flanges, bawuloli, da bututu, inda babban abubuwan hulɗar iskar gas da ruwa ne, abubuwan da ake buƙata don fashe a cikin ƙwanƙwasa walda sun fi taka tsantsan, kuma ana buƙatar gabaɗaya cewa bai kamata a sami faɗuwar ƙirar walda ba.

Ana buƙatar gyare-gyare ko sake yin gyare-gyare kaɗan a kan saman kayan aiki kamar flanges da bawuloli

Yi amfani da bawul ɗin GFH-D507Mo na kamfanin mu kayan aikin walda na musamman don surfacing, babu fasa a saman.

2. Babban abubuwan da ke haifar da tsatsauran ra'ayi mai ƙarfi

Akwai abubuwa da yawa da ke haifar da tsagewa. Don waldi mai wuyar jure lalacewa, ana iya raba shi zuwa fashe masu zafi waɗanda za a iya samun su bayan wucewa ta farko ko ta biyu, da tsagewar sanyi waɗanda ke bayyana bayan wucewa ta biyu ko ma bayan duk walda.

Tsatsa mai zafi:

A lokacin aikin walda, ƙarfe a cikin kabu na weld da yankin da zafi ya shafa yana sanyaya zuwa yankin zafin jiki mai zafi kusa da layin solidus don samar da fasa.

Ciwon sanyi:

Cracks generated a yanayin zafi kasa da solidus (kimanin a martensitic canji zafin jiki na karfe) yafi faruwa a matsakaici-carbon karafa da high-ƙarfi low-alloy karfe da matsakaici-gawa karfe.

Kamar yadda sunan ya nuna, an san samfurori masu wuyar gaske don tsayin daka. Duk da haka, neman tauri a cikin injiniyoyi kuma yana haifar da raguwar filastik, wato, haɓakar raguwa. Gabaɗaya magana, yin sama sama da HRC60 baya maida hankali sosai ga faɗuwar zafin rana da aka haifar yayin aikin walda. Duk da haka, m surfacing waldi tare da taurin tsakanin HRC40-60, idan akwai wani bukata ga fasa, The intergranular fasa a cikin walda tsari ko liquefaction da multilateral fashe lalacewa ta hanyar babba waldi dutsen dutse zuwa zafi-shafi yankin na ƙananan weld. dutse yana da wahala sosai.

Ko da an shawo kan matsalar tsagewar zafi sosai, za a iya fuskantar barazanar tsagewar sanyi bayan an gama walda, musamman ma kayan da ba su da ƙarfi kamar walda mai tauri, wanda ya fi jin sanyi. Mummunan tsagewa yawanci yakan faru ne sakamakon tsagewar sanyi

3. Muhimman abubuwan da ke shafar ɓarna mai jure lalacewa a saman tudu da dabarun guje wa fasa

Muhimman abubuwan da za a iya bincikowa lokacin da tsagewar ke faruwa a cikin tsarin lalacewa mai wuya kamar haka, kuma an ba da shawarar dabarun da suka dace don kowane abu don rage haɗarin fashewa:

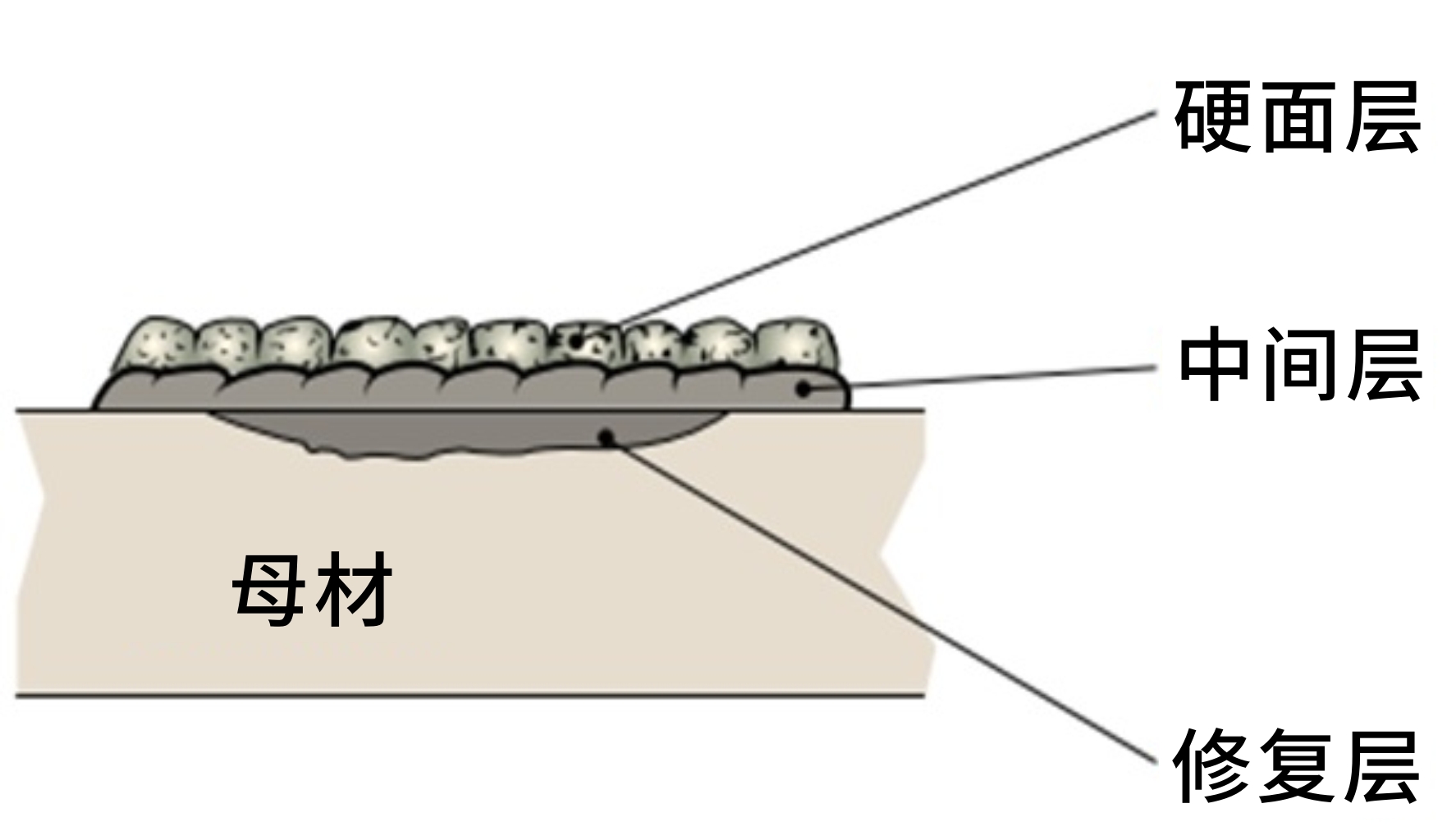

1. Kayan tushe

Tasirin karfen tushe akan rufin ƙasa mai jurewa yana da mahimmanci sosai, musamman ga kayan aiki tare da ƙasa da yadudduka 2 na walda. A abun da ke ciki na tushe karfe kai tsaye rinjayar kaddarorin weld bead. Zaɓin kayan aiki daki-daki ne wanda ke buƙatar kulawa kafin fara aiki. Misali, idan bawul workpiece tare da manufa taurin kusan HRC30 yana surfacing da simintin ƙarfe tushe abu, ana bada shawara a yi amfani da walda abu tare da dan kadan kasa tauri, ko ƙara Layer na bakin karfe matsakaici Layer, don haka kamar yadda. guje wa abun cikin carbon da ke cikin kayan tushe daga ƙara haɗarin fashewar walda.

Ƙara tsaka-tsaki a kan kayan tushe don rage haɗarin fashewa

2. Abubuwan amfani da walda

Don tsarin da ba ya buƙatar fashe, manyan abubuwan amfani da walda na carbon da high-chromium ba su dace ba. Ana ba da shawarar yin amfani da kayan aikin walda na tsarin martensitic, kamar mu GFH-58. Yana iya walda saman dutsen da ba shi da fa'ida lokacin da taurin ya kai HRC58 ~ 60, musamman dacewa da wuraren aikin da ba na tsari ba waɗanda ke da ƙura da ƙasa da dutse.

3. Shigar da zafi

Gina kan rukunin yanar gizon yana ƙoƙarin yin amfani da mafi girma na halin yanzu da ƙarfin lantarki saboda annashuwa akan inganci, amma matsakaicin rage ƙarfin halin yanzu da ƙarfin lantarki kuma na iya rage faruwar faɗuwar zafi yadda ya kamata.

4. Kula da yanayin zafi

Multi-Layer da Multi-pass hardfacing waldi za a iya daukarsa a matsayin wani tsari na ci gaba da dumama, sanyaya da reheating ga kowane wucewa, don haka zafin jiki kula da muhimmanci sosai, daga preheating kafin waldi zuwa wuce zafin jiki a lokacin surfacing Control, har ma da sanyaya tsari bayan. waldi, na bukatar babban hankali.

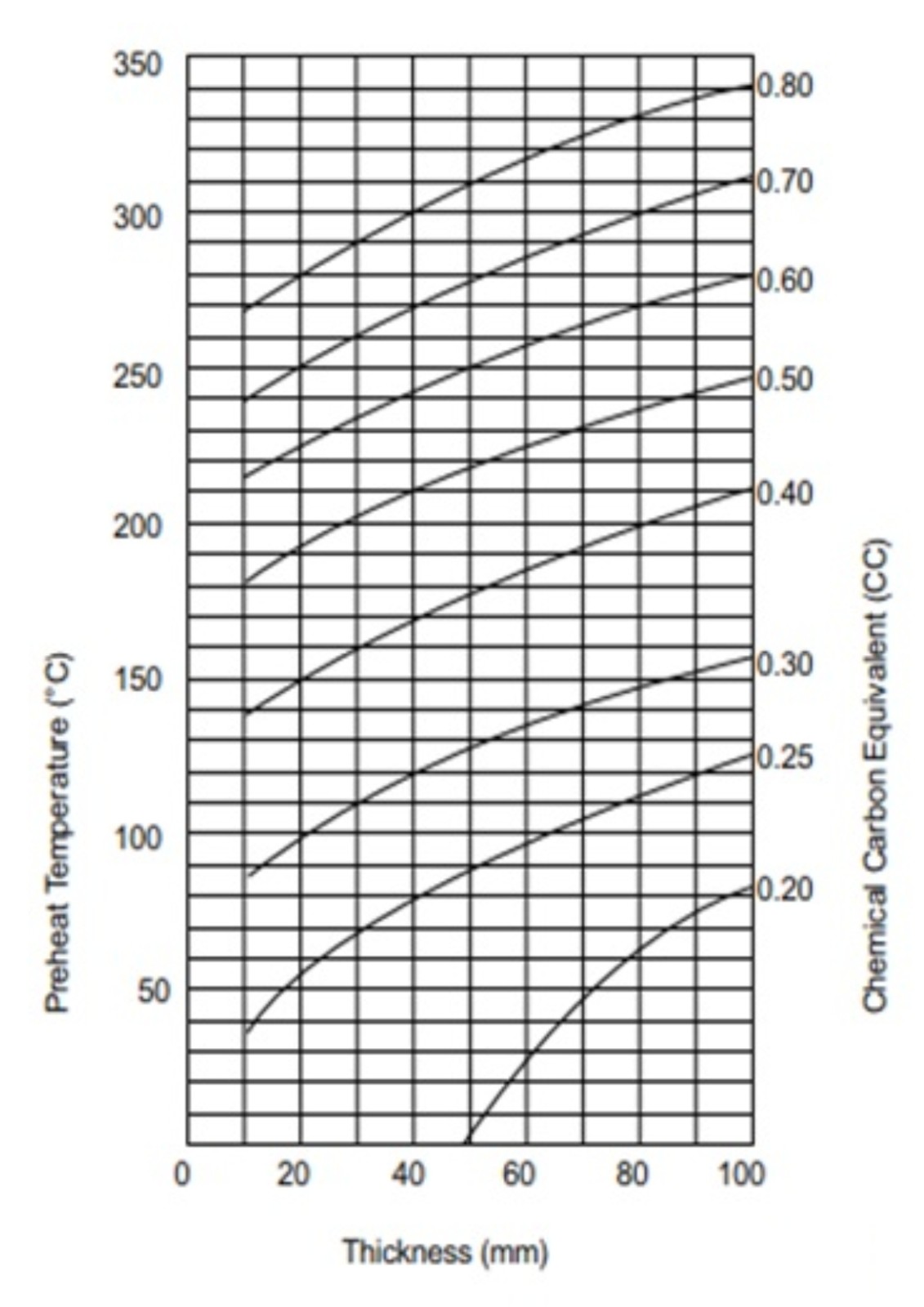

The preheating da waƙa zafin jiki na surfacing waldi suna kusa da alaka da carbon abun ciki na substrate. Ƙarƙashin ƙasa a nan ya haɗa da kayan tushe ko tsaka-tsakin tsaka-tsakin, da kasan ƙasa mai wuya. Gabaɗaya magana, saboda abun cikin carbon na ƙarfe mai wuyar da aka ajiye Idan abun cikin yana da girma, ana ba da shawarar kiyaye zafin hanya sama da digiri 200. Duk da haka, a cikin ainihin aiki, saboda tsayin daka na weld ɗin, an sanyaya ɓangaren gaba na bead ɗin a ƙarshen wucewa ɗaya, kuma wucewa na biyu zai iya haifar da fashewa a cikin yankin da zafin jiki ya shafa na substrate. . Sabili da haka, idan babu kayan aiki masu dacewa don kula da zafin jiki na tashar ko preheat kafin waldawa, ana bada shawarar yin aiki a cikin sassa da yawa, gajeren welds, da ci gaba da waldawa a cikin sashe guda don kula da zafin jiki na tashar.

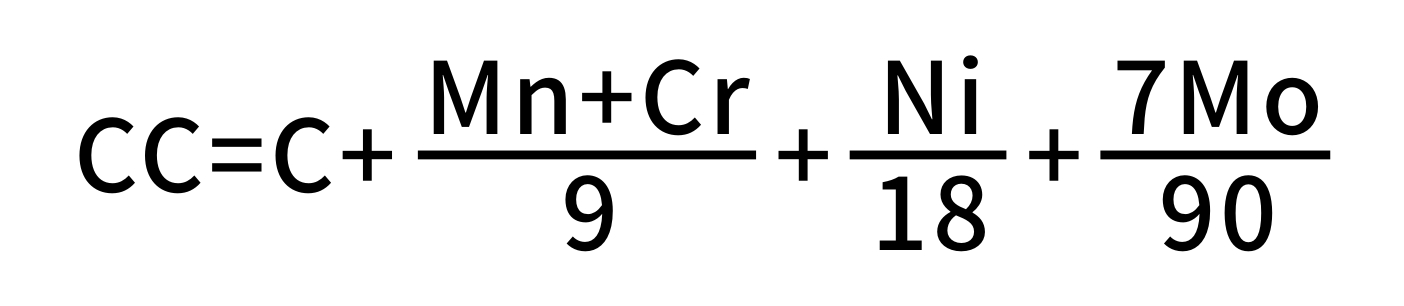

Dangantaka tsakanin abun ciki na carbon da zafin zafin jiki

Jinkirin sanyaya bayan surfacing shima yana da matukar mahimmanci amma sau da yawa matakin watsi da shi, musamman ga manyan kayan aiki. Wani lokaci ba shi da sauƙi don samun kayan aiki masu dacewa don samar da jinkirin yanayin sanyi. Idan babu wata hanyar da za a magance wannan halin da ake ciki, za mu iya ba da shawarar sake amfani da shi Hanyar da aka raba, ko kuma kauce wa walƙiya a lokacin da zafin jiki ya ragu, don rage hadarin sanyi.

Hudu. Kammalawa

Har yanzu akwai bambance-bambancen masana'antun ɗaya ɗaya cikin buƙatun hardfacing don fasa cikin aikace-aikace masu amfani. Wannan labarin yana yin tattaunawa mai tsauri bisa ƙayyadaddun ƙwarewa. Mu kamfanin ta wuya surface lalacewa-resistant jerin waldi consumables da m kayayyakin ga abokan ciniki zabi daban-daban taurin da aikace-aikace. Barka da zuwa tuntubar kasuwanci a kowace gunduma.

Aikace-aikacen masana'anta mai hade da lalacewa

| Abu | Kare gas | girman | Babban | HRC | Amfani |

| GFH-61-0 | Kare kai | 1.6 2.8 3.2 | C: 5.0 ku: 0.6 Mn: 1.2 C: 28.0 | 61 | Dace da niƙa ƙafafun, siminti mixers, bulldozers, da dai sauransu. |

| GFH-65-0 | Kare kai | 1.6 2.8 3.2 | C: 5.0 C: 22.5 Mo: 3.2 V: 1.1 W: 1.3 Nb:3.5 | 65 | Ya dace da babban zafin jiki na cire ƙurar fanka, kayan ciyar da tanderu, da sauransu. |

| GFH-70-O | Kare kai | 1.6 2.8 3.2 | C: 5.0 C: 30.0 B: 0.3 | 68 | Ana iya amfani da abin nadi na kwal, ja fatalwa, kayan karba, murfin kwal, injin niƙa, da sauransu. |

Aikace-aikace a masana'antar siminti

| Abu | Kare gas | girman | Babban | HRC | Amfani |

| GFH-61-0 | Kare kai | 1.6 2.8 3.2 | C: 5.0 ku: 0.6 Mn: 1.2 C: 28.0 | 61 | Dace da nika dutse rollers, siminti mixers, da dai sauransu |

| GFH-65-0 | Kare kai | 1.6 2.8 3.2 | C: 5.0 C: 22.5 Mo: 3.2 V: 1.1 W: 1.3 Nb:3.5 | 65 | Ya dace da babban zafin jiki na cire ƙurar fanka, kayan ciyar da tanderu, da sauransu. |

| GFH-70-O | Kare kai | 1.6 2.8 3.2 | C: 5.0 C: 30.0 B: 0.3 | 68 | Dace da niƙa dutse rollers, fatalwa hakora, karɓar hakora, grinders, da dai sauransu. |

| GFH-31-S | GXH-81 | 2.8 3.2 | C: 0.12 ku: 0.87 Mn: 2.6 Mo: 0.53 | 36 | Ana amfani da sassa na ƙarfe-zuwa-ƙarfe irin su ƙafafun rawani da gatari |

| GFH-17-S | GXH-81 | 2.8 3.2 | C: 0.09 ku: 0.42 Mn: 2.1 C: 2.8 Mo: 0.43 | 38 | Ana amfani da sassa na ƙarfe-zuwa-ƙarfe irin su ƙafafun rawani da gatari |

Aikace-aikacen Shuka Karfe

| Abu | Kare gas | girman | Babban | HRC | Amfani |

| GFH-61-0 | Kare kai | 1.6 2.8 3.2 | C: 5.0 ku: 0.6 Mn: 1.2 C: 28.0 | 61 | Dace da sintering shuka sanduna tanderu, fatalwa hakora, lalacewa-resistant faranti, da dai sauransu. |

| GFH-65-0 | Kare kai | 1.6 2.8 3.2 | C: 5.0 C: 22.5 Mo: 3.2 V: 1.1 W: 1.368 Nb:3.5 | 65 | |

| GFH-70-0 | Kare kai | 1.6 2.8 3.2 | C: 5.0 C: 30.0 B: 0.3 | 68 | |

| GFH-420-S | GXH-81 | 2.8 3.2 | C: 0.24 ku: 0.65 Mn: 1.1 C: 13.2 | 52 | Ya dace da yin nadi, isar da rolls, tuƙi rolls, da sauransu. |

| GFH-423-S | GXH-82 | 2.8 3.2 | C: 0.12 ku: 0.42 Mn: 1.1 C: 13.4 Mo: 1.1 V: 0.16 Nb:0.15 | 45 | |

| GFH-12-S | GXH-81 | 2.8 3.2 | C: 0.25 ku: 0.45 Mn: 2.0 C: 5.8 Mo: 0.8 V: 0.3 W:0.6 | 51 | Anti-m lalacewa Properties, dace da karfe farantin factory tuƙi Rolls, tsunkule Rolls da sa sassa tsakanin karafa |

| GFH-52-S | GXH-81 | 2.8 3.2 | C: 0.36 ku: 0.64 Mn: 2.0 Ni: 2.9 C: 6.2 Mo: 1.35 V: 0.49 | 52 |

Aikace-aikacen ma'adinai

| Abu | Kare gas | girman | Babban | HRC | Amfani |

| GFH-61-0 | Kare kai | 1.6 2.8 3.2 | C: 5.0 ku: 0.6 Mn: 1.2 C: 28.0 | 61 | Ana amfani da masu tonawa, masu kan titi, zaɓe, da sauransu. |

| GFH-58 | CO2 | 1.6 2.4 | C: 0.5 ku: 0.5 Mun: 0.95 Ni: 0.03 C: 5.8 Mo: 0.6 | 58 | Dace da surfacing waldi a gefen dutse bayarwa trough |

| GFH-45 | CO2 | 1.6 2.4 | C: 2.2 ku: 1.7 Mun: 0.9 C: 11.0 Mo: 0.46 | 46 | Dace da sawa sassa tsakanin karafa |

Aikace-aikacen Valve

| Abu | Kare gas | girman | Babban | HRC | Amfani |

| GFH-D507 | CO2 | 1.6 2.4 | C: 0.12 S: 0.45 Mun: 0.4 Ni: 0.1 C:13 Mo: 0.01 | 40 | Dace da surfacing waldi na bawul sealing surface |

| GFH-D507Mo | CO2 | 1.6 2.4 | C: 0.12 S: 0.45 Mun: 0.4 Ni: 0.1 C:13 Mo: 0.01 | 58 | Dace da surfacing waldi na bawuloli tare da babban lalata |

| GFH-D547Mo | Sandunan hannu | 2.6 3.2 4.0 5.0 | C: 0.05 Mn: 1.4 ku: 5.2 Shafin: 0.027 S: 0.007 Ni: 8.1 C: 16.1 Mo: 3.8 Nb:0.61 | 46 | Dace da high zafin jiki, high matsa lamba bawul surfacing waldi |

More information send to E-mail: export@welding-honest.com

Lokacin aikawa: Dec-26-2022