I. Bayani

Tare da saurin haɓaka masana'antar kera injuna, sifofi na welded kamar injiniyoyi na zamani da tasoshin matsin lamba suna haɓaka zuwa ƙara girma da yanayin nauyi. Abubuwan buƙatun don ƙimar ƙarfin ƙarfe suna samun girma kuma mafi girma, ba wai kawai buƙatar ingantaccen kaddarorin inji ba, amma har ma mai kyau aiwatarwa, weldability da juriya.

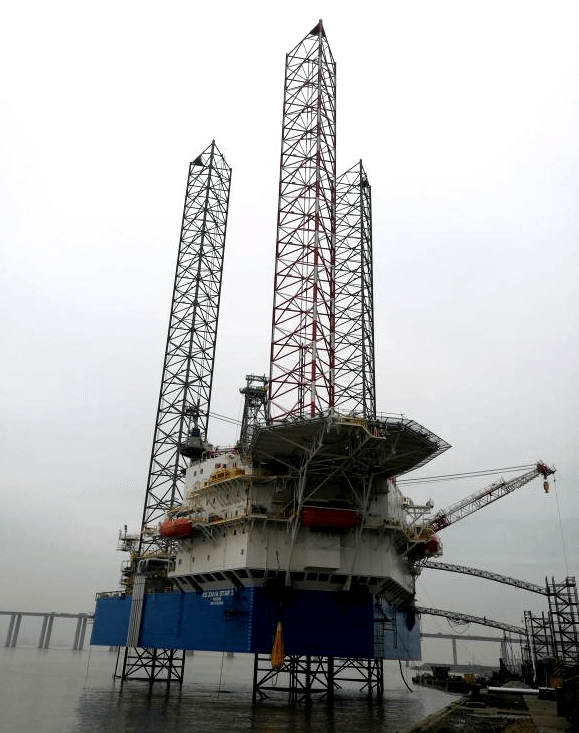

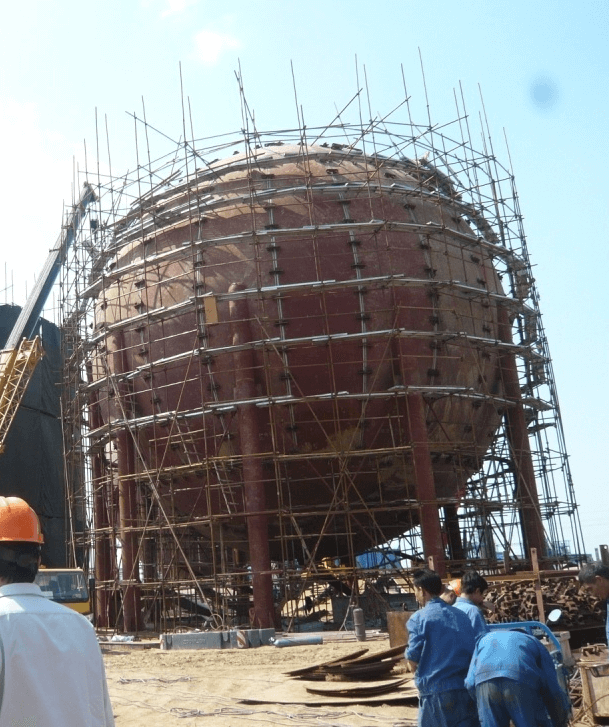

Q690 karfe nasa ne mai ƙarfi welded tsarin karfe, inda Q tsaye ga yawan amfanin ƙasa, da kuma 690 yana nufin yawan amfanin ƙasa ƙarfin matakin ne 690MPa. 690MPa sa karfe yana da yawan amfanin ƙasa da ƙarfi mai ƙarfi, kuma ana amfani dashi ko'ina a cikin injin ma'adinai na kwal, injin gini, injiniyan ruwa, dandamali na teku, tasoshin matsa lamba, da dai sauransu, yana buƙatar ƙarfe don samun ƙarfin yawan amfanin ƙasa da ƙarancin gajiya, kyakkyawan tasiri tauri, Cold formability da kyau kwarai weldability.

2.Brief gabatarwar Q690 karfe farantin karfe

| Ƙasashen Duniya Q690 karfe grade | Q690A | Q690B | Q690C | Q690D | Q690E | Q690F |

| Tsuntsaye | Zafafan birgima | Quenching + zafin jiki (yankin da aka kashe da fushi) | ||||

| Abubuwan da ke cikin najasa | Babban P/S | low P/S | Mafi ƙarancin P/S | |||

| Bukatun girgiza | NO | Matsanancin zafin jiki na al'ada | 0 ℃ | -20 ℃ | -40 ℃ | -60 ℃ |

Koyaya, a halin yanzu, farantin karfe na 690MPa don jiragen ruwa na cikin gida galibi ya dogara ne akan ma'aunin Turai EN10028-6, kuma an jera abubuwan da suka dace a cikin tebur mai zuwa:

| Samar da 690MPA karfe don ƙa'idodin matsa lamba na Turai | P690Q | Saukewa: P690QH | Saukewa: P69QL1 | Saukewa: P69QL2 |

| Tsuntsaye | lallausan hatsin da aka kashe da karfe | |||

| ƙarfi bukatun | Haihuwa≥690MPa(farantin kauri≤50mm) Tensile770-940MPa | |||

| Abubuwan da ke cikin najasa | P≤0.025%, S≤0.015% | P≤0.02%, S≤0.010% | ||

| Bukatun girgiza | 20℃≥60J | 20℃≥60J | 0≥60J | -20℃≥40J |

| 0≥40J | 0≥40J | -20℃≥40J | -40℃≥27J | |

| -20℃≥27J | -20℃≥27J | -40℃≥27J | -60℃≥27J | |

| Babban wuraren aikace-aikacen | Tsarin matsi ko tasoshin matsa lamba tare da ƙananan buƙatun taurin tasiri | Spherical tank tare da high fasaha bukatun | Ruwan ruwa mai ruwan iskar gas | |

A matsayin farantin karfe don tankunan ajiya da ƙarfin matsa lamba, dole ne ya sami ƙarfin ƙarfi da ƙarfi, aikin lankwasa sanyi da ƙarancin ƙima. Ko da yake quenched da tempered Q690 karfe yana da ƙananan carbon daidai kuma m Properties, shi har yanzu yana da wani hardening hali idan aka kwatanta da sauran 50/60kg matsa lamba jirgin ruwa steels, da kuma post-weld zafi magani ake bukata. Duk da haka, babban adadin gwaje-gwajen gwaje-gwaje sun nuna cewa don kayan aikin walda na ƙarfe na Q690, ƙarancin zafin jiki mai ƙarfi mai ƙarfi zai ragu sosai bayan maganin zafi mai zafi, kuma tare da haɓakar yanayin zafi mai zafi da rage yawan zafin jiki, tabarbarewar yanayin zafi. na waldi m tauri zai zama mafi bayyane. Sabili da haka, yana da mahimmanci mai mahimmanci don haɓaka ƙarfin ƙarfi, ƙarfin ƙarfi mai ƙarfi, da sandunan walda masu zafi don Q690 karfe don samun nasarar amfani da ƙarfe Q690 zuwa kayan aiki mai ɗaukar nauyi, rage kayan ƙarfe, da rage farashin masana'anta.

3.Brief gabatarwar mu Q690 karfe waldi sanda

| Abu | Daidaitawa | Nau'in fata | Polarity | babban fasali |

| GEL-118M | AWS A5.5 E1108MISO 18275-BE7618-N4M2A | Iron foda low hydrogen irin | DC+/AC | Ƙarfin ƙarfi, ƙarancin hydrogen, ingantaccen haɓakawa, ingantaccen kayan aikin injiniya, ingantaccen tasirin tasirin zafi mai ƙarfi a -50 ° C, da tasirin tasiri mai kyau a -40 ° C bayan jiyya mai zafi. |

| GEL-758 | AWS A5.5 E11018-GISO 18275-BE7618-G A | Iron foda low hydrogen irin | DC+/AC | Ultra-low hydrogen, babban jigon inganci, babban tauri (-60℃≥70J), tasiri mai kyau a -40/-50 ℃ bayan magani mai zafi |

| GEL-756 | AWS A5.5 E11016-GISO 18275-BE7616-G A | Low hydrogen potassium irin | AC/DC+ | Ultra-low hydrogen, AC / DC + dual-manufa, babban tasiri tauri (-60 ℃≥70J), tasiri mai kyau a -50/-60 ℃ bayan zafi magani |

4.Q690 karfe waldi sanda nuni inji yi nuni

| Abu | As-welded inji Properties | ||||||

| Samar da MPA | Tsawon MPA | Tsawa % | Tasirin dukiya J/℃ | Gwajin rediyo | Hydrogen diffusible ml/100g | ||

| -50 ℃ | -60 ℃ | ||||||

| AWS A5.5 E11018M | 680- 760 | ≥760 | ≥20 | ≥27 | - | I | - |

| ISO 18275-B E7618-N4M2A | 680- 760 | ≥760 | ≥18 | ≥27 | - | I | - |

| GEL-118M | 750 | 830 | 21.5 | 67 | 53 | I | 3.2 |

| Saukewa: AWS A5.5E1101X-G | ≥ 670 | ≥760 | ≥15 | - | - | I | - |

| ISO 18275B E761X-GA | ≥ 670 | ≥760 | ≥13 | - | - | I | - |

| GEL-758 | 751 | 817 | 19.0 | 90 | 77 | I | 3.4 |

| GEL-756 | 764 | 822 | 19.0 | 95 | 85 | I | 3.6 |

Misali:

1. "X" da aka yiwa alama a cikin jajayen rubutu a cikin Ma'aunin Amurka da Turai yana wakiltar nau'in fata na miyagun ƙwayoyi.

2. GEL-758 yayi daidai da E11018-G da ISO 18275-B E7618-G A a cikin AWS da ka'idodin ISO bi da bi.

3. GEL-756 yayi daidai da E11016-G da ISO 18275-B E7616-G A a cikin AWS da ka'idodin ISO bi da bi.

Mechanical Properties na Q690 karfe waldi sanda a zafi magani jihar

| Abu | Mechanical Properties na zafi bi da jihar | ||||||

| Samar da MPA | Tsawon MPA | Tsawa % | Tasirin dukiya J/℃ | Dumama ℃ * h | |||

| -40 ℃ | -50 ℃ | -60 ℃ | |||||

| Manufar aikin | ≥ 670 | ≥760 | ≥15 | ≥60 | ≥52 | ≥47 | 570*2 |

| GEL-118M | 751 | 827 | 22.0 | 85 | 57 | - | 570*2 |

| GEL-758 | 741 | 839 | 20.0 | 82 | 66 | 43 | 570*2 |

| GEL-756 | 743 | 811 | 21.5 | 91 | 84 | 75 | 570*2 |

Misali:

1. AWS da ka'idodin ISO ba su da buƙatun aikin aikin zafi don samfuran da ke sama. Ana taƙaita magungunan zafi na sama bisa ga yanayin fasaha na yawancin abokan ciniki kuma don tunani kawai.

2. GEL-118M yana da tasirin tasiri mai kyau a -40 ° C bayan maganin zafi, kuma tasirin tasiri a -50 ° C ya fi bayyane.

3. Bayan maganin zafi, GEL-758 yana da tasirin tasiri mai kyau a -40 ° C, tasiri mai kyau a -50 ° C, da kuma lalacewa a fili a ƙananan zafin jiki a -60 ° C.

4. Ƙarƙashin ƙananan zafin jiki na rashin ƙarfi na GEL-756 bayan maganin zafi yana da ƙananan ƙananan, kuma ƙananan zafin jiki a -60 ° C har yanzu yana da kyau.

Weldability nuni na Q690 karfe waldi sanda

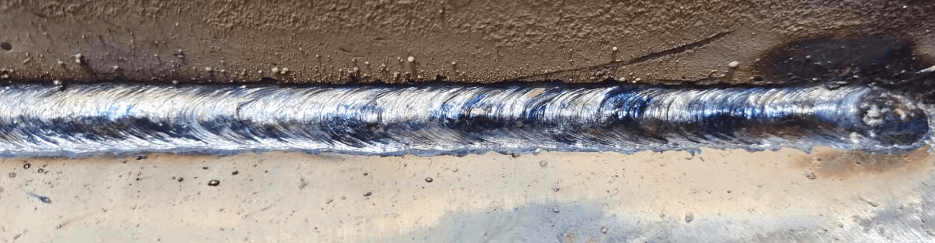

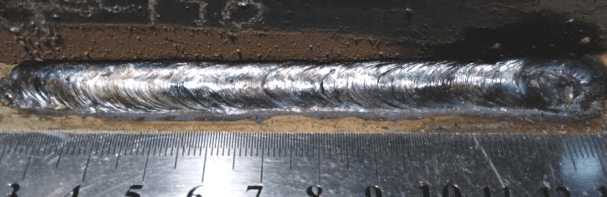

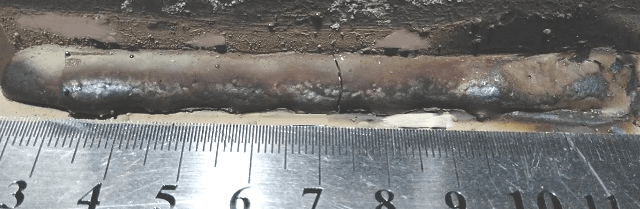

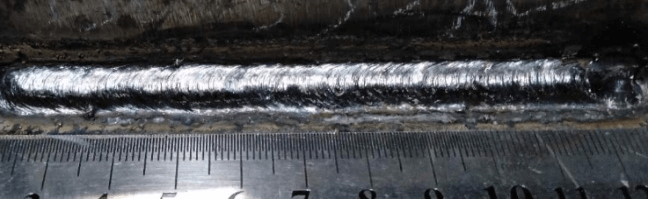

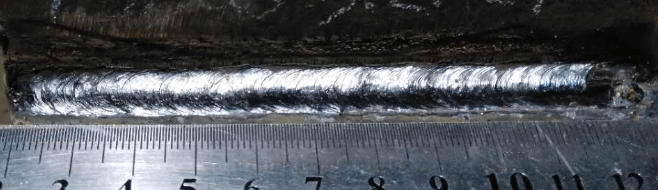

GEL-118M lebur fillet waldi kafin da kuma bayan slag cire (DC+)

Kafin da kuma bayan GEL-758 lebur fillet waldi slag cire (DC+)

GEL-756 lebur fillet waldi kafin da kuma bayan slag cire (AC)

GEL-756 lebur fillet waldi kafin da kuma bayan slag cire (DC+))

Q690 karfe waldi sanda waldi kariya

1. Adana kayan aikin walda:

Ana ba da shawarar abubuwan amfani da walda don adana su a ƙarƙashin yanayin zafi akai-akai da busassun yanayi, kuma a sanya su a kan pallets ko shelves, guje wa hulɗa kai tsaye tare da bango da ƙasa.

2. Shiri kafin walda:

Cire damshi sosai, tsatsa, tabon mai, da sauransu a saman kayan tushe, kuma a guji danshin saman ko fallasa ruwan sama da dusar ƙanƙara.

3. Matakan hana iska:

Lokacin walda, ya kamata a tabbatar da cewa iyakar gudun iska a wurin waldawar bai wuce 2m/s ba. In ba haka ba, ya kamata a dauki matakan kariya.

4. Preheating:

Ana ba da shawarar yin amfani da kayan dumama lantarki don dumama kayan aikin zuwa sama da 150 ° C kafin waldawa. Kafin dasa shuki, ya kamata a sanya shi a zafin jiki na 150 ° C.

5. Layer da kula da zafin jiki na hanya:

A lokacin duk aikin walda, zafin jiki na tsaka-tsakin kada ya zama ƙasa da zafin jiki na preheating, kuma shawarar wucewar zafin jiki shine 150-220 ° C.

6. Cire hydrogen bayan walda:

Bayan an welded din dinkin, nan da nan sai a kara yawan zafin wutar lantarki zuwa 250 ℃ ~ 300 ℃, sai a rika dumama shi tsawon awanni 2 zuwa 4, sannan a yi sanyi a hankali.

① Idan kauri daga cikin workpiece ne ≥50mm, da rike lokaci ya kamata a mika zuwa 4-6 hours, sa'an nan sanyaya sannu a hankali.

② A ƙarƙashin yanayin babban kauri da babban hani, ana iya ƙara ƙarin dehydrogenation bayan waldawa zuwa kauri 1/2, kuma a hankali sanyaya zuwa zafin jiki na tsaka-tsaki.

7. Tsarin bene:

Ana ba da shawarar yin amfani da walda mai yawa-Layer da Multi-pass, kuma saurin walda ya kamata a kiyaye shi a koyaushe.

More information send to E-mail: export@welding-honest.com

Lokacin aikawa: Janairu-10-2023