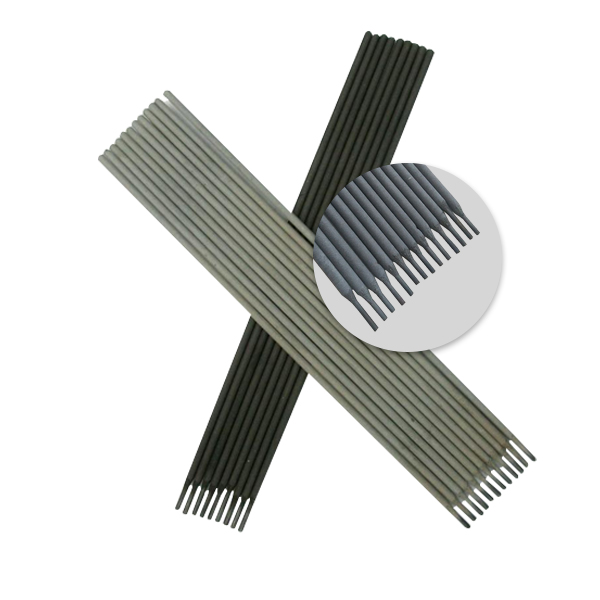

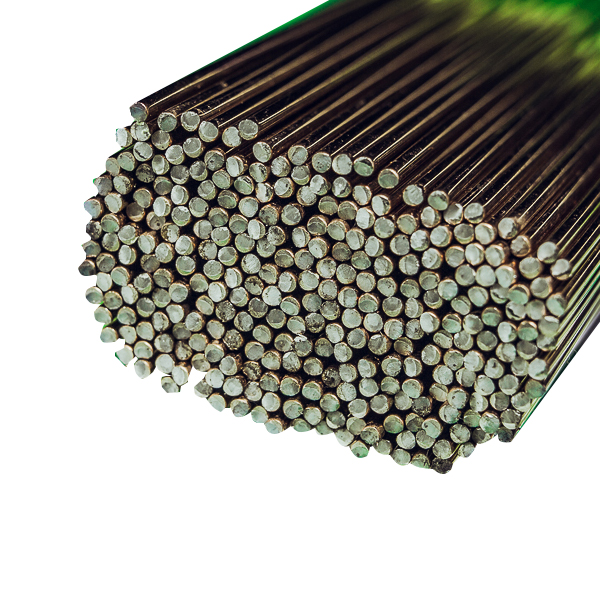

High Carbon steels Manual lantarki E9818-G Soldering yin

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T dokokin | - | ≥1.00 | 0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| Dokokin AWS | - | - | - | - | - | - | - | - | - | - |

| MISALI DARAJAR | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||

| GB/T dokokin | - | - | - | - | - | |||||

| Dokokin AWS | - | - | - | - | - | |||||

| MISALI DARAJAR | 915 | 992 | - | 65/-20 | 16 | |||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

980Mpa super high ƙarfi low ferrohydrogen foda irin low gami karfe lantarki.

Tsayayyen baka, ƙaramin fantsama, kyakkyawan cire slag

Kyakkyawan aikin walda mai kyau duka, ƙarancin zafin jiki mai kyau, juriya mai tsauri da ƙarancin tasirin zafi.

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T dokokin | - | ≥1.00 | 0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| Dokokin AWS | - | - | - | - | - | - | - | - | - | - |

| MISALI DARAJAR | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||

| GB/T dokokin | - | - | - | - | - | |||||

| Dokokin AWS | - | - | - | - | - | |||||

| MISALI DARAJAR | 915 | 992 | - | 65/-20 | 16 | |||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Ku rubuta sakonku anan ku aiko mana