Babban Carbon Karfe Flux cored waya walda kayan haɗi

Application & Standard

1. Dace da walda na carbon karfe da daidai ƙarfin tukunyar jirgi, bututun, abin hawa,

gini, gada da sauran sifofi, kamar Q235.

2. Matsayin da muka hadu da shi: GB/T5117 E4315, AWS, ISO2560-A: E 35 3 B 2 2, ISO 2560-B: E4315A

A carbon abun ciki na high carbon karfe ne in mun gwada da high, da weldability ne in mun gwada da matalauta, waldi zuwa preheat, bayan waldi zuwa jinkirin sanyaya ko 350 digiri na low zazzabi tempering jiyya, da takamaiman tsawon zafi magani yana da kauri daga cikin workpiece ƙayyade.

Sinadarin narkakkar karfe (%) Abubuwan sinadaran C Mn Si SP Mo

Ƙimar garanti &le~1.75 ≤0.60 &lele~0.45

Babban sakamako ≤0.10 ~ 1.40 ≤ 0.40&lele; 0.025 ~ 0.30

Kayayyakin inji Gwajin abubuwa Rm(MPa) ReL ko Rp0.2(Mpa) A(%) KV2(J)

Ƙimar garanti ≥590 ≥490 ≥15 ≥27(-30℃)

Sakamakon Gabaɗaya 620 zuwa 680 ≥500 20 zuwa 28 ≥47

Yadawa hydrogen abun ciki na narkakkar karfe: ≤4.0ml/100g(Glycerol Hanyar)

Gano kuskuren X-ray: daraja Ⅰ

Magana na yanzu (AC, DC+) diamita na lantarki (mm) φ3.2φ4.0φ5.0

Welding halin yanzu (A) 80 ~ 140 110 ~ 210 160 ~ 230

Siffofin

1. Low sodium hydrogen electrode tare da tsayayye baka, kyakkyawa siffa, kankanin fantsama, da kuma m ripple.

2. Daidaitaccen halayen inji, filastik mai ƙarfi, juriya mai tasiri, da juriya mai tsauri.

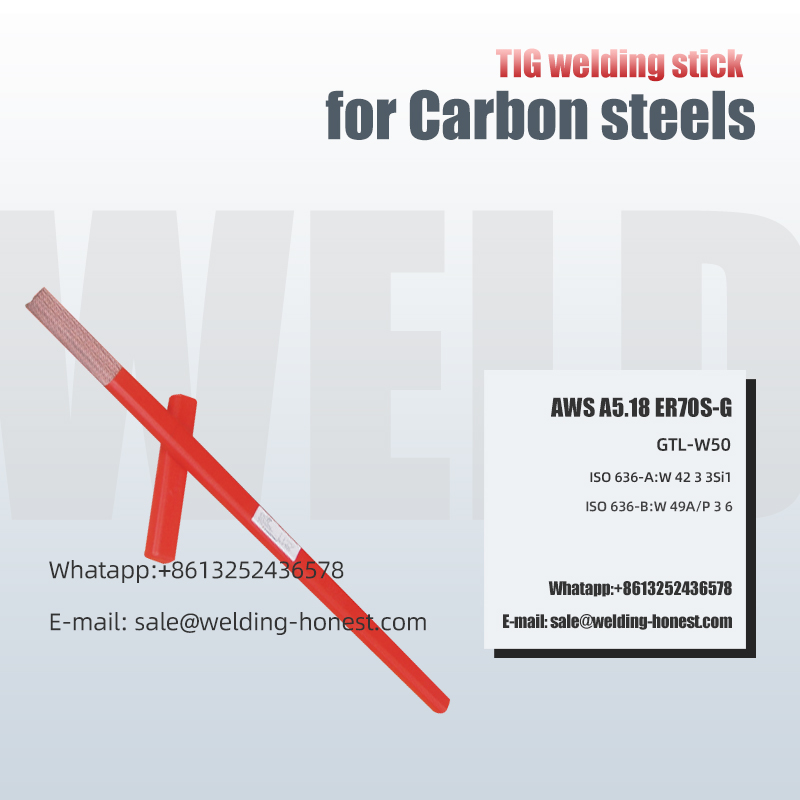

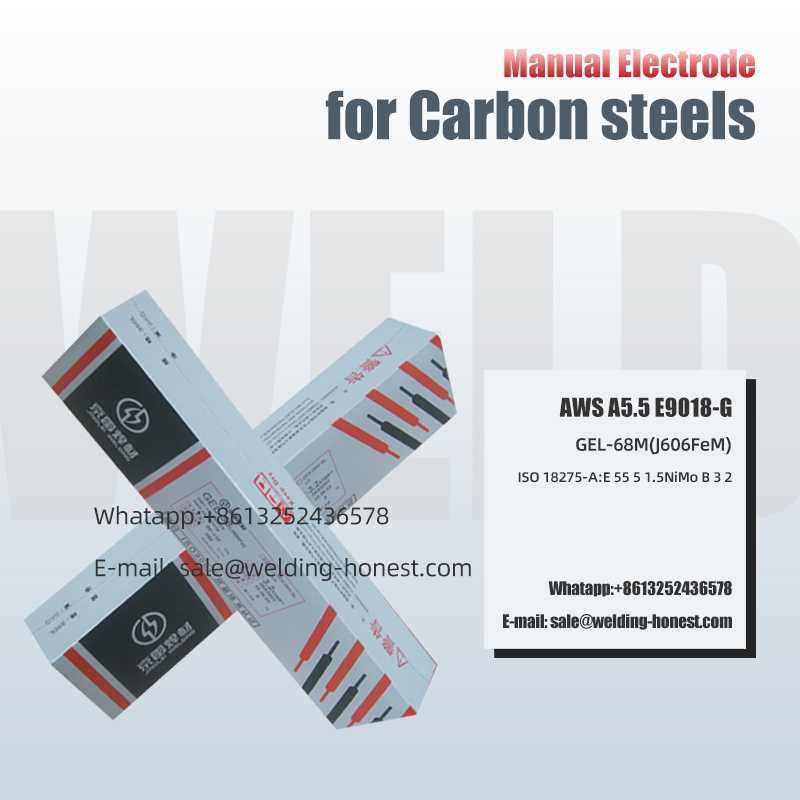

Babban samfuranmu sune chromium-molybdenum gami, gami da masu jure zafi, gami da tushen nickel, duplex da super duplex gami. Ciki har da na'urar arc na hannu, MIG/MAG, TIG, wayan baka mai nutsewa da waya iri-iri. Waɗannan samfuran ana amfani da su sosai a cikin walƙiya na ƙarancin gami da ƙarfe, ƙarfe mai jure zafi, gami da nickel tushe gami da baƙin ƙarfe daban-daban tare da babban ƙarfi da ƙarancin zafin jiki.

Kamfanin & Factory

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T dokokin | - | ≥1.00 | 0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| Dokokin AWS | - | ≥1.00 | 0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.030 | 0.030 | ≥0.10 |

| MISALI DARAJAR | 0.068 | 1.28 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||||||

| GB/T dokokin | 490 | 590 | 620*1 | 27/-20 | 16 | |||||||||

| Dokokin AWS | 530 | 620 | 620*1 | - | 17 | |||||||||

| MISALI DARAJAR | 600 | 685 | 620*1 | 80/-50 | 25 | |||||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

NOTE:

H/W: a kwance matsayi waldi

O/W: walƙiya matsayi sama da kai

AL'AMURAN AL'AMARI

Takaddun shaida

Gabatarwar abun ciki na samfur da kaddarorin inji:

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T dokokin | - | ≥1.00 | 0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.10 |

| Dokokin AWS | - | ≥1.00 | 0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.030 | 0.030 | ≥0.10 |

| MISALI DARAJAR | 0.068 | 1.28 | 0.28 | 0.03 | 1.65 | 0.42 | 0.011 | 0.007 | 0.01 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||||||

| GB/T dokokin | 490 | 590 | 620*1 | 27/-20 | 16 | |||||||||

| Dokokin AWS | 530 | 620 | 620*1 | - | 17 | |||||||||

| MISALI DARAJAR | 600 | 685 | 620*1 | 80/-50 | 25 | |||||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

NOTE:

H/W: a kwance matsayi waldi

O/W: walƙiya matsayi sama da kai