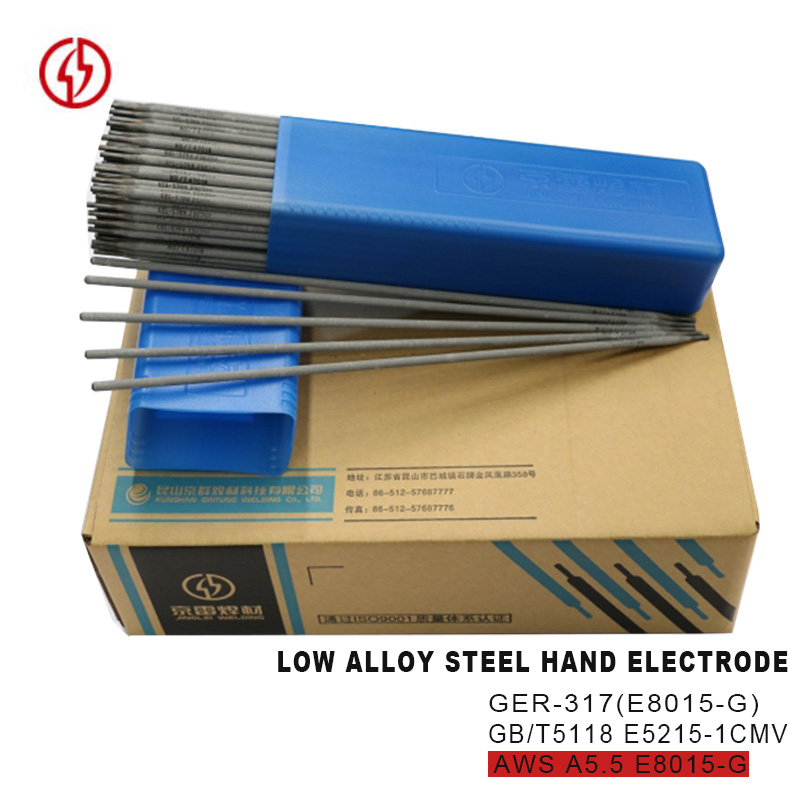

AWS E8015-G Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Waya Na'urorin haɗi

Aikace-aikace & Standard&Lura:

AWS E8015-G irin hannu waldi lantarki ga zafi-resistant karfe ne dace da high zafin jiki da kuma high matsa lamba tanderu bututun ikon tashar, high zafin jiki roba sinadaran inji, man fetur tace kayan aiki, da dai sauransu tare da aiki zafin jiki a kasa 540 ℃, kamar 12CrMoV. Kuma za a iya amfani da waldi aiki zafin jiki kasa 540 ℃, kamar 15CrMo pearlite zafi resistant karfe. Hakanan ana iya amfani dashi don walda 30CrMnSi simintin ƙarfe. Yawancin aikace-aikacen walda tare da ƙananan buƙatun abun ciki na carbon za a iya amfani da su zuwa na'urar lantarki ta hannun mu mai jure zafi. Hakanan ya shahara sosai a kasuwa, kuma sakamakon ra'ayoyin kasuwa shima yana da kyau sosai. Muna ɗaukar fasahar samar da ci gaba, sarrafa sarrafa kayan albarkatun ƙasa, sarrafawa da samarwa, dubawar samfur, sabis na tallace-tallace na kowane daki-daki, don samar wa abokan ciniki mafi kyawun lantarki da sabis na waya.

Siffofin

AWS E8015-G nau'in waldawa na hannu don ƙarfe mai jure zafi shine ƙaramin nau'in sodium hydrogen nau'in na'urar waldawa ta hannu, tare da barga mai ƙarfi, ƙarancin fantsama, gyare-gyare mai kyau, sauƙi mai sauƙi, kyakkyawan aikin X-Ray, ƙayyadaddun kayan aikin injin, na iya kiyaye babban tasiri tauri. karkashin yanayin maganin zafi. Wannan hannun lantarki ne mai pearlite zafi resistant karfe lantarki dauke da 0.5% molybdenum, 1% chromium, vanadium, da yin amfani da DC baya waldi aiki, na iya zama duk matsayi waldi, bukatar preheat zuwa 250 ~ 300 ℃ kafin waldi. Post-welding zafi magani ya kamata a za'ayi a 730 ± 15 ℃ * 2h daidai da daidaitattun bukatun na waldi kayan. Kuma kafin waldawa, wajibi ne don cire mai, tsatsa, danshi da sauran aiki akan walda.

Kamfanin & Factory

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S | V |

| GB/T dokokin | 0.05-0.12 | 0.90 | 0.60 | 0.80-1.50 | 0.40-0.65 | 0.03 | 0.030 | 0.10-0.35 |

| Dokokin AWS | - | ≥1.00 | 0.80 | ≥0.30 | ≥0.20 | 0.04 | 0.030 | ≥0.10 |

| MISALI DARAJAR | 0.07 | 0.75 | 0.35 | 1.15 | 0.5 | 0.013 | 0.018 | 0.150 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||||||

| GB/T dokokin | 460 | 550 | 730*2 | - | 15 | |||||||||

| Dokokin AWS | 460 | 550 | 730*2 | - | 19 | |||||||||

| MISALI DARAJAR | 510 | 610 | 730*2 | 180/Nature zazzabi | 23 | |||||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

BAYANIN CIKI:

| SANARWA | TSORO | PCS/1KG | NUNA/1KG | |||

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | mm 350 | 27 PCS | 5KG | |||

| 4.0mm | mm 350 | 16 PCS | 5KG | |||

| 5.0mm ku | mm 350 | 12 PCS | 5KG | |||

Al'amuran Al'ada

Takaddun shaida

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S | V |

| GB/T dokokin | 0.05-0.12 | 0.90 | 0.60 | 0.80-1.50 | 0.40-0.65 | 0.03 | 0.030 | 0.10-0.35 |

| Dokokin AWS | - | ≥1.00 | 0.80 | ≥0.30 | ≥0.20 | 0.04 | 0.030 | ≥0.10 |

| MISALI DARAJAR | 0.07 | 0.75 | 0.35 | 1.15 | 0.5 | 0.013 | 0.018 | 0.150 |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | MAGANIN ZAFIN ℃xh | IMAPACT DARAJAR J/℃ | LONGATION(%) | |||||||||

| GB/T dokokin | 460 | 550 | 730*2 | - | 15 | |||||||||

| Dokokin AWS | 460 | 550 | 730*2 | - | 19 | |||||||||

| MISALI DARAJAR | 510 | 610 | 730*2 | 180/Nature zazzabi | 23 | |||||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| WUTAR LANTARKI (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

BAYANIN CIKI:

| SANARWA | TSORO | PCS/1KG | NUNA/1KG | |||

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | mm 350 | 27 PCS | 5KG | |||

| 4.0mm | mm 350 | 16 PCS | 5KG | |||

| 5.0mm ku | mm 350 | 12 PCS | 5KG | |||