AWS A5.13 ENiCrFe-1 nickel alloys Manual electrode walda kayan haɗi

Application & Standard

ANA IYA AMFANI DA WANNAN ELECTRODE MAI SURFAACING ELECTRODE DOMIN LINING SLEVE OF SHAFT SEEVE, YANKE GEFE NA KAYAN FIBER NA CHEMICAL, SAWTOOTH, SCROW PUSH ROD, HIGH zafin jiki da HIGH matsa lamba bawul DA HIGH matsa lamba ETC. Rashin ƙarancin aikin aikin ya kamata ya zama ƙasa da Ra12.5μm, kuma ya kamata a cire tsatsa, mai da sauran datti sosai. Matrix kada ya kasance yana da fasa, pores, yashi da sauran lahani, kuma gefuna da sasanninta ya kamata a zagaye. Kafin surfacing, ya kamata a zaɓi yanayin zafi daban-daban bisa ga kayan da ake amfani da su don preheating. Lokacin da matrix abu ne pearlitic zafi-resistant karfe ko martensitic bakin karfe da sauran kayan da matalauta waldi yi, da austenitic bakin karfe surfacing Layer ya kamata a welded a kan matrix surface, sa'an nan da cobalt tushen gami ya kamata a surfacing bayan m aiki zuwa ga. inganta tsattsauran ra'ayi kuma ku guje wa fasa. Ko dai AC ko DC baka walda wutar lantarki za a iya amfani da D802 da D812 electrodes. Ana ba da shawarar samar da wutar lantarki na walda DC.

Siffofin

GEH-SL12 titanium calcium mai rufi cobalt-base surfacing lantarki. Cobalt-cr-tungsten alloy ana amfani dashi azaman ainihin waya. Ana ba da shawarar haɗin baya na DC. Karfe mai rufi na iya kula da juriya mai kyau da juriya na lalata a 650 ℃. Kafin waldawa, dole ne a gasa a 300-350 ℃ na awa 1; Ya kamata a cire Layer na hardening a saman tushe na ƙarfe don guje wa fashewa da raguwa. Bisa ga girman tushe karfe workpiece da irin tushe karfe, shi dole ne a preheated a 300-600 ℃, da kuma kananan halin yanzu short baka waldi ya dace.

Kamfanin & Factory

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T dokokin | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| Dokokin AWS | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| MISALI DARAJAR | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

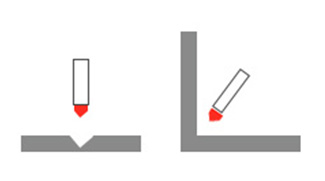

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| WUTAR LANTARKI (Amp) | Flat/a kwance walda | 69-95 | 70-115 | 95-145 | ||||

| A tsaye/a kan walda | 55-80 | 65-110 | 80-130 | |||||

AL'AMURAN AL'AMARI

Takaddun shaida

Gabatarwar abun da ke ciki da kayan aikin injiniya

KASHIN KIMIYYA:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T dokokin | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| Dokokin AWS | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| MISALI DARAJAR | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| WUTAR LANTARKI (Amp) | Flat/a kwance walda | 69-95 | 70-115 | 95-145 | ||||

| A tsaye/a kan walda | 55-80 | 65-110 | 80-130 | |||||