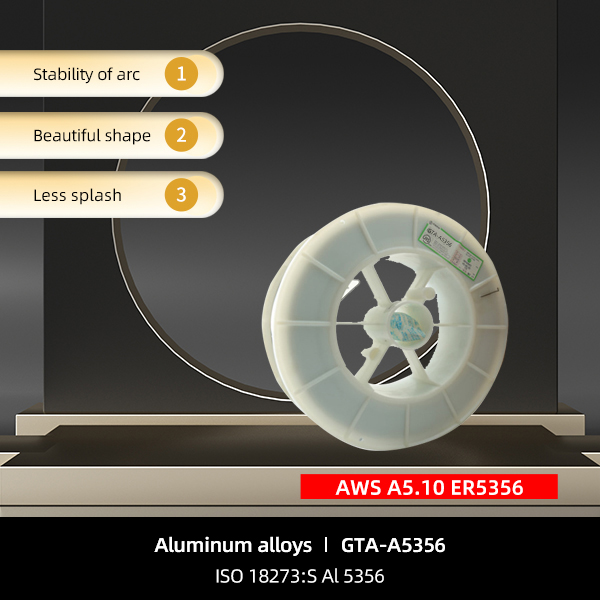

Aluminum alloys MIG ER5356 walda kayan haɗi

KASHIN KIMIYYA:

| ALOY(wt%) | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | S |

| GB/T dokokin | 0.25 | 0.40 | 0.10 | 0.05-0.2 | 4.5-5.5 | 0.05-0.2 | 0.10 | 0.06-0.2 | 0.0005 | Margin |

| Dokokin AWS | 0.25 | 0.40 | 0.10 | 0.05-0.2 | 4.5-5.5 | 0.05-0.2 | 0.10 | 0.06-0.2 | 0.0008 | Margin |

| MISALI DARAJAR | 0.15 | 0.10 | 0.03 | 0.15 | 5.20 | 0.1 | 0.05 | 0.12 | 0.0003 | Margin |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | Karfe na iyaye | LONGATION(%) | Maganin zafi | ||||||

| GB/T dokokin | - | - | - | - | - | ||||||

| Dokokin AWS | - | - | - | - | - | ||||||

| MISALI DARAJAR | 100 | 250 | 5454-H112 | 16 | AW | ||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 1.2 | 1.6 | 2.0 | 2.4 | 3.0 | |||||

| Volt | 19-25 | 21-26 | 21-29 | 24-30 | 26-32 | |||||

| Am | 140-300 | 180-300 | 250-360 | 250-400 | 300-450 | |||||

| Gudun iskar gas (l/min) | 10-20 | 15-22 | 28-30 | 28-30 | 28-30 | |||||

| Gudun walda cm/min | 25-40 | 25-40 | 25-40 | 20-40 | 20-40 | |||||

Babban bangaren shine ALMg5Cr.

Welding ko surface surfacing na 5% magnesium simintin gyare-gyare da ƙirƙira aluminum gami, duniya waldi abu, high ƙarfi, mai kyau malleability, mai kyau lalata juriya.

Ciyarwar waya mai santsi, barga mai konewa, fantsama da wuya yana yin kyau.

-

308,000 ton VLCC na danyen mai

-

Ton 300,000 na Keɓan Ruwa da Tankin Ajiya (FPSO)

-

Harbin Electric - Sanmen, Haiyang MSR

KASHIN KIMIYYA:

| ALOY(wt%) | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | S |

| GB/T dokokin | 0.25 | 0.40 | 0.10 | 0.05-0.2 | 4.5-5.5 | 0.05-0.2 | 0.10 | 0.06-0.2 | 0.0005 | Margin |

| Dokokin AWS | 0.25 | 0.40 | 0.10 | 0.05-0.2 | 4.5-5.5 | 0.05-0.2 | 0.10 | 0.06-0.2 | 0.0008 | Margin |

| MISALI DARAJAR | 0.15 | 0.10 | 0.03 | 0.15 | 5.20 | 0.1 | 0.05 | 0.12 | 0.0003 | Margin |

DUKIYAR INJI:

| DUKIYA | KARFIN KYAUTA (MPa) | KARFIN ARZIKI(MPa) | Karfe na iyaye | LONGATION(%) | Maganin zafi | ||||||

| GB/T dokokin | - | - | - | - | - | ||||||

| Dokokin AWS | - | - | - | - | - | ||||||

| MISALI DARAJAR | 100 | 250 | 5454-H112 | 16 | AW | ||||||

SHAWARAR MATSALAR welding:

| BAYANIN DIAMETERS(mm) | 1.2 | 1.6 | 2.0 | 2.4 | 3.0 | |||||

| Volt | 19-25 | 21-26 | 21-29 | 24-30 | 26-32 | |||||

| Am | 140-300 | 180-300 | 250-360 | 250-400 | 300-450 | |||||

| Gudun iskar gas (l/min) | 10-20 | 15-22 | 28-30 | 28-30 | 28-30 | |||||

| Gudun walda cm/min | 25-40 | 25-40 | 25-40 | 20-40 | 20-40 | |||||

Ku rubuta sakonku anan ku aiko mana